ACCELERATING GROWTH

ACROSS MULTIPLE DIMENSIONS

As we enter the next era of innovation and growth, in 2019 we began to see the benefits of our strategic ventures. Innovations such as ALD and epitaxy are the growth engines of the company, helping drive our expansion. In Singapore, we are making new infrastructure investments as we develop locally and collaborate globally. We continue to expand the ASMI team, hiring additional employees who will enable us to realize new opportunities. Our strong financial performance underlines the true impact of our progress, enabling us to share our success with shareholders. Together, these advances help us to accelerate growth across multiple dimensions.

KEY PERFORMANCE

EMPLOYEES

GROWING PEOPLE

GROWING BUSINESS

CUSTOMERS

INVESTING LOCALLY

COLlABORATING

GLOBALLY

SHAREHOLDERS

SHAPING THE FUTURE

EXPANDING OUR

GROWTH ENGINE

SOCIETY

UNDERSTANDING

OUR IMPACT

INCREASING

OUR VALUE

MESSAGE FROM THE CEO

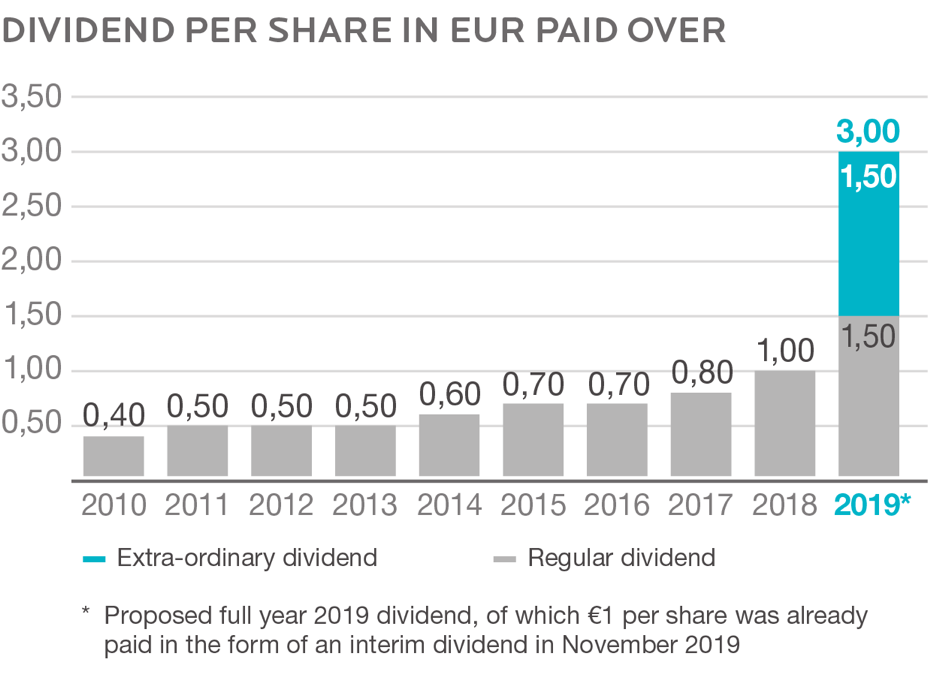

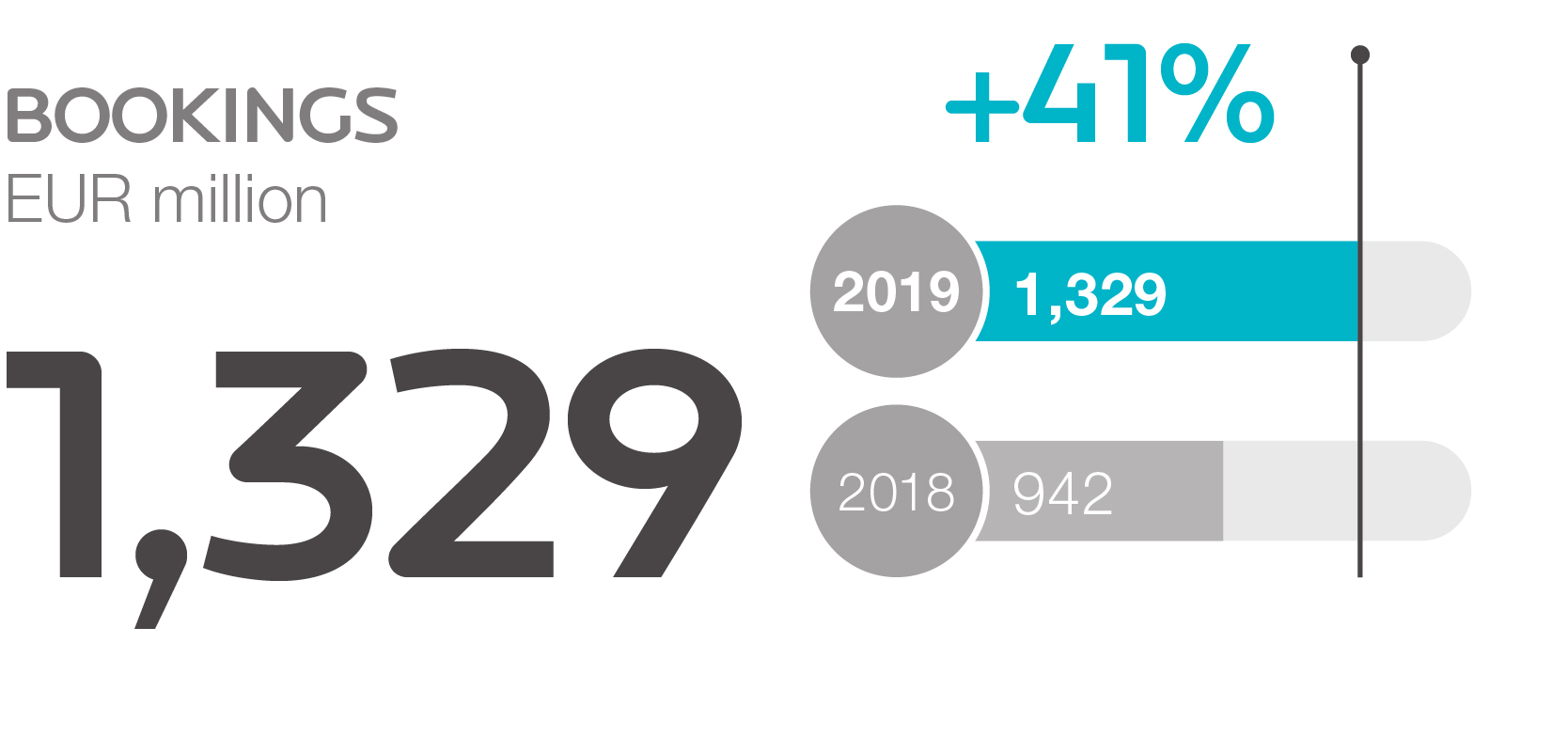

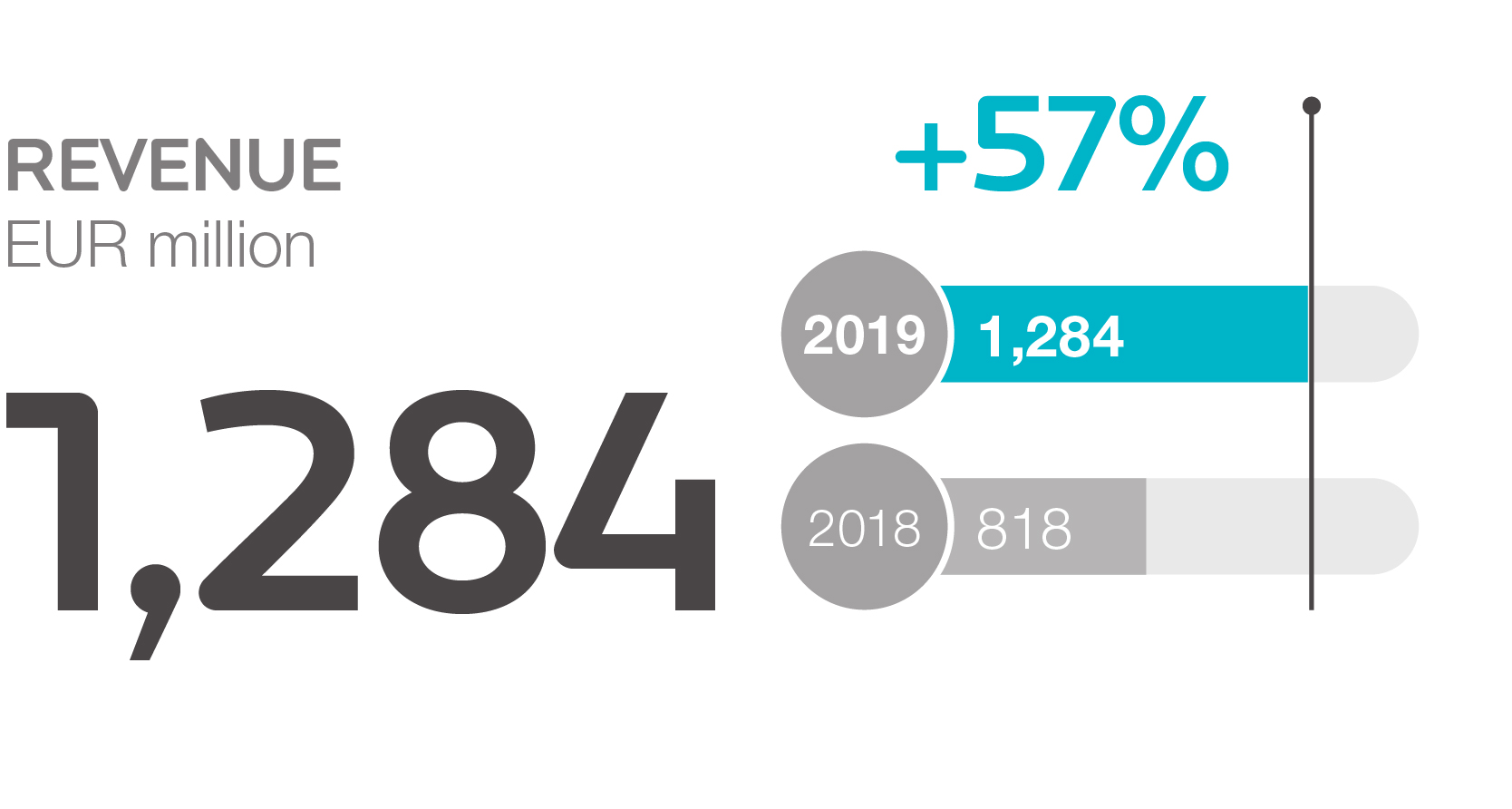

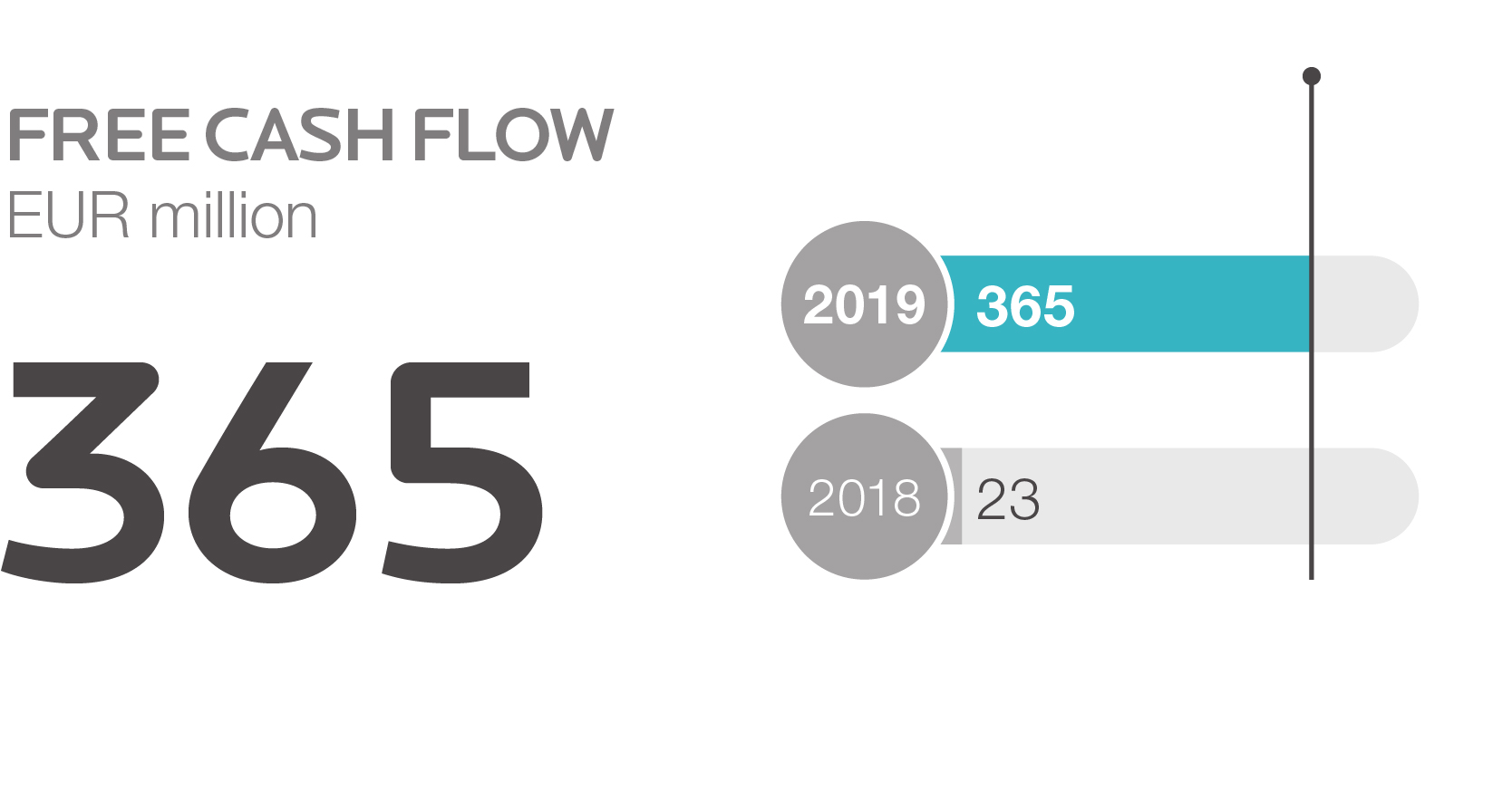

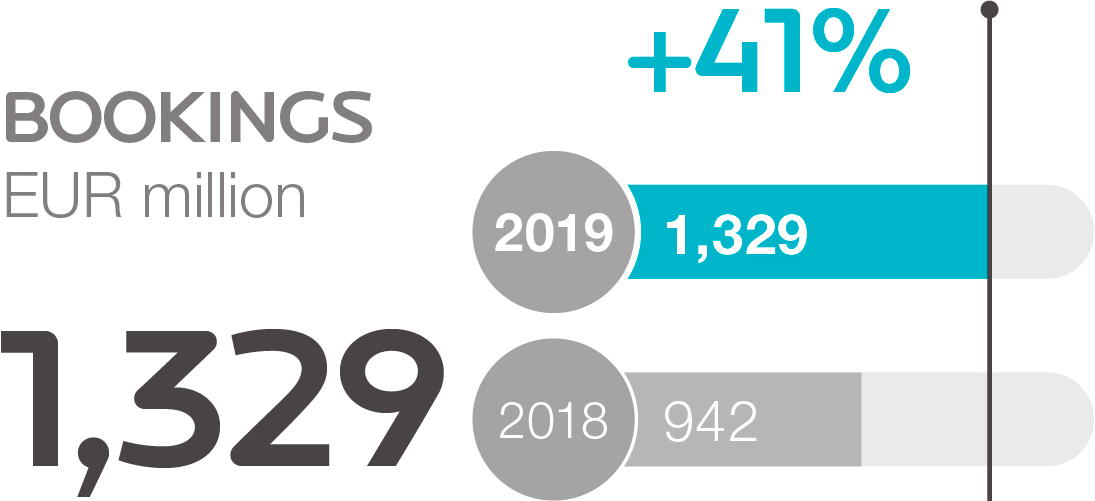

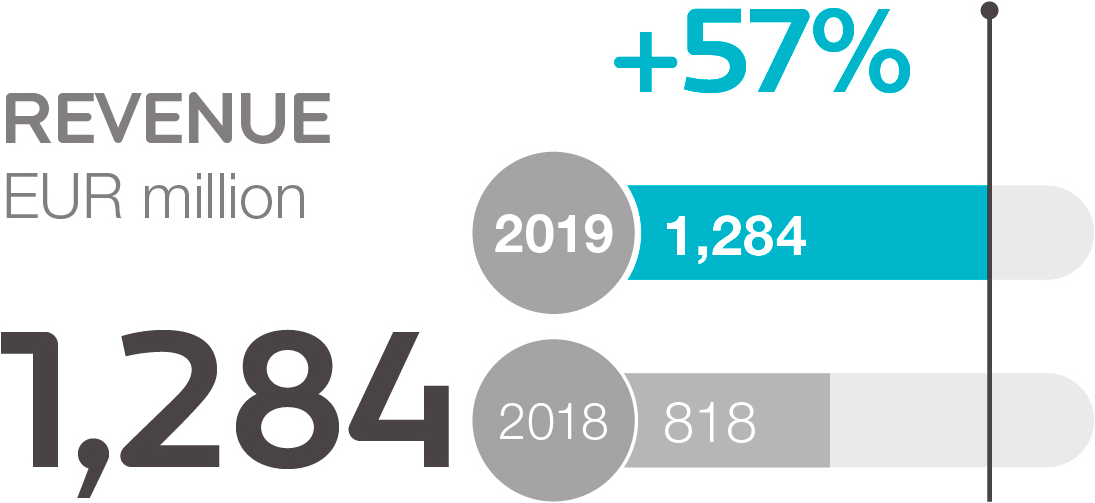

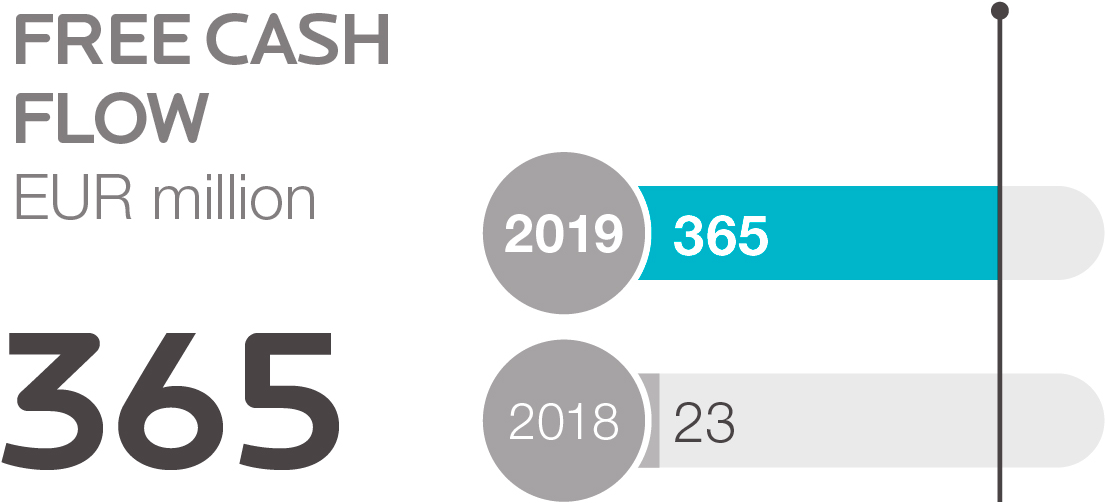

2019 has been a highly successful year for ASMI. We increased our sales by 57%, including proceeds from the settlement with Kokusai Electric Corporation (KEC). Excluding these proceeds sales increased by 37%, strongly outperforming the wafer fab equipment (WFE) market. Our growth was driven by solid spending in the logic/foundry segment on the most advanced nodes. We delivered record high financial results and we booked meaningful progress in our Corporate Responsibility programs.

KEY PERFORMANCE

FINANCIAL

NON-FINANCIAL

Employees

GROWING PEOPLE,

GROWING BUSINESS

![]() Our focus on building a culture of learning and innovation, while emphasizing diversity and inclusion across the workplace, helps us develop momentum.

Our focus on building a culture of learning and innovation, while emphasizing diversity and inclusion across the workplace, helps us develop momentum.

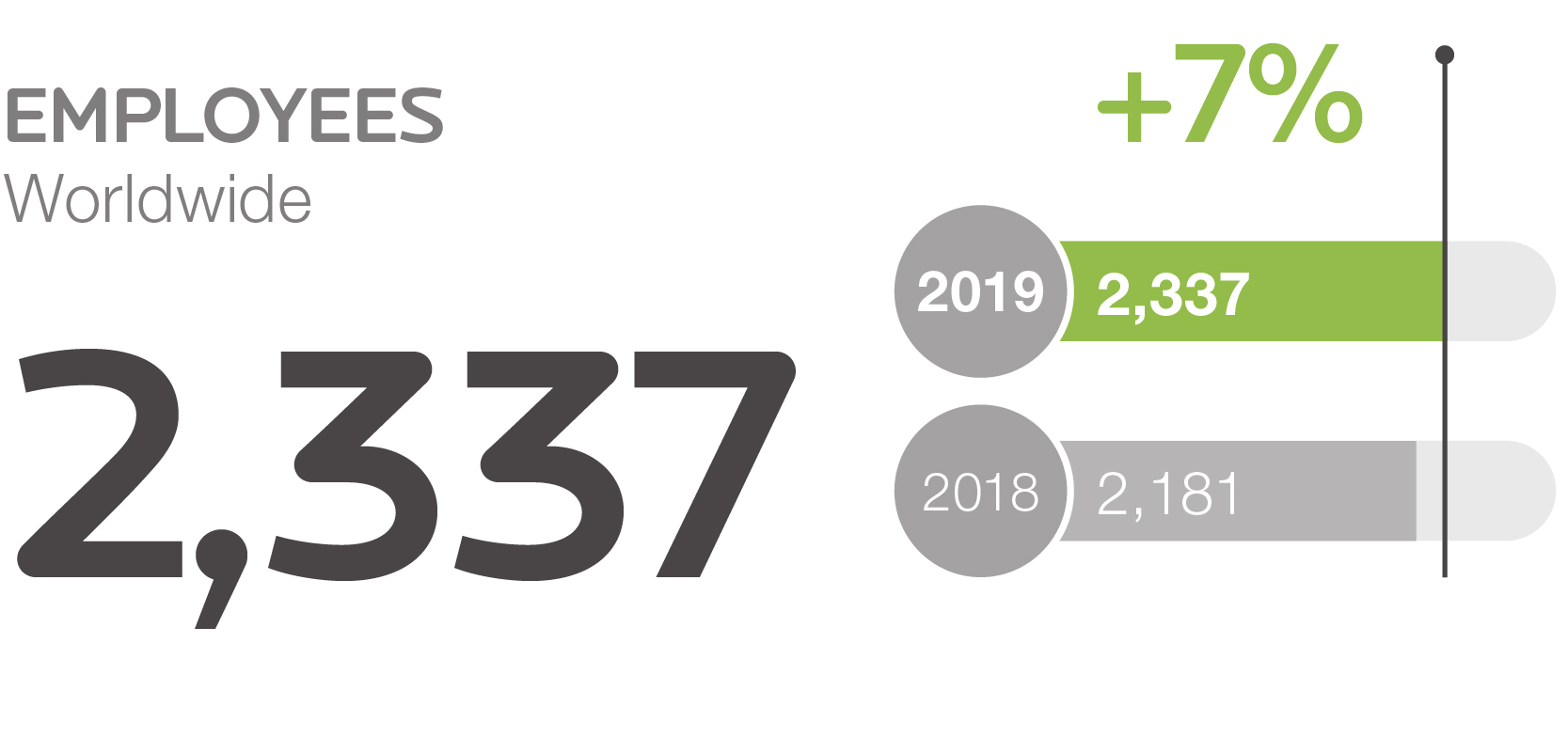

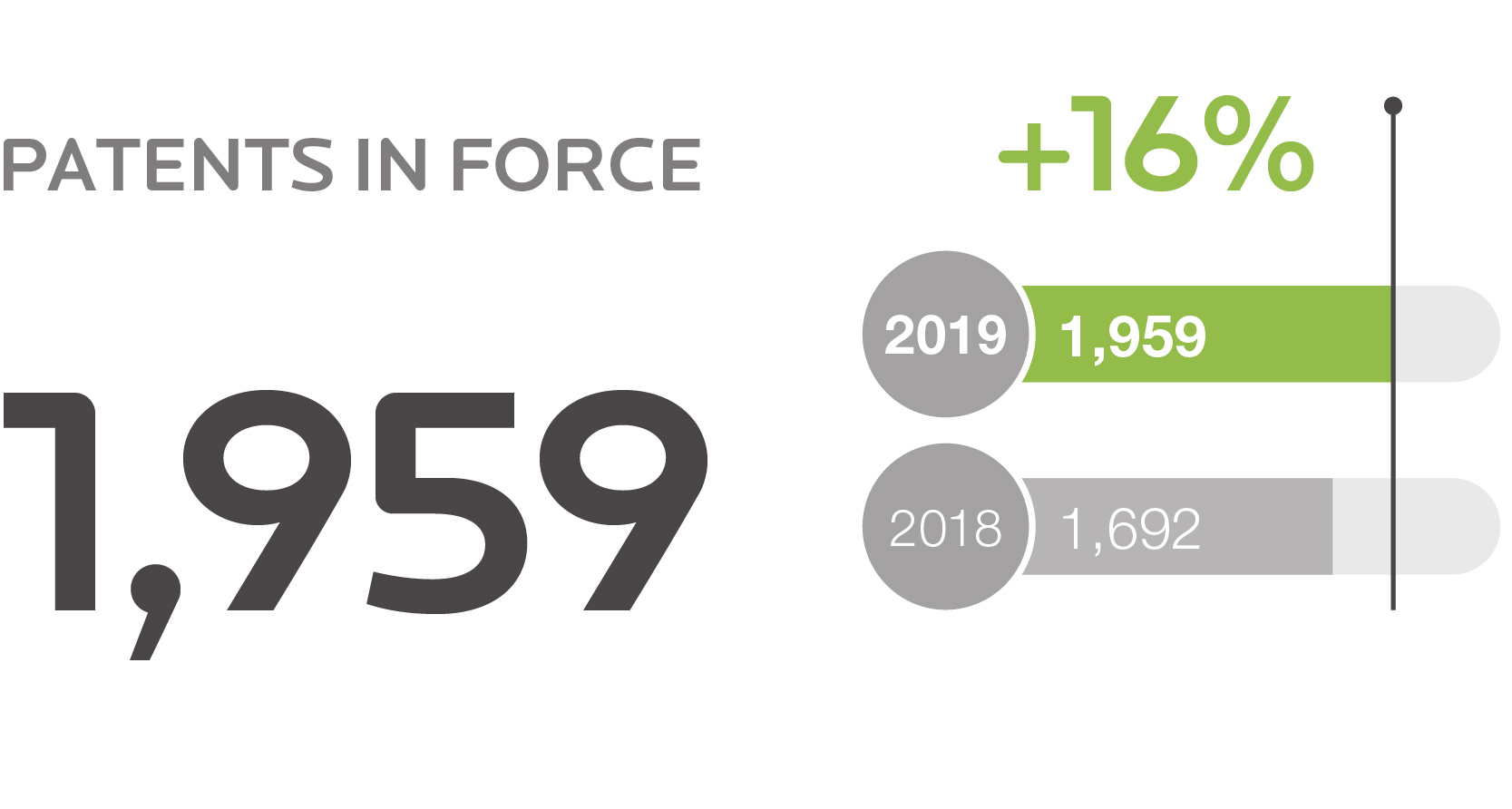

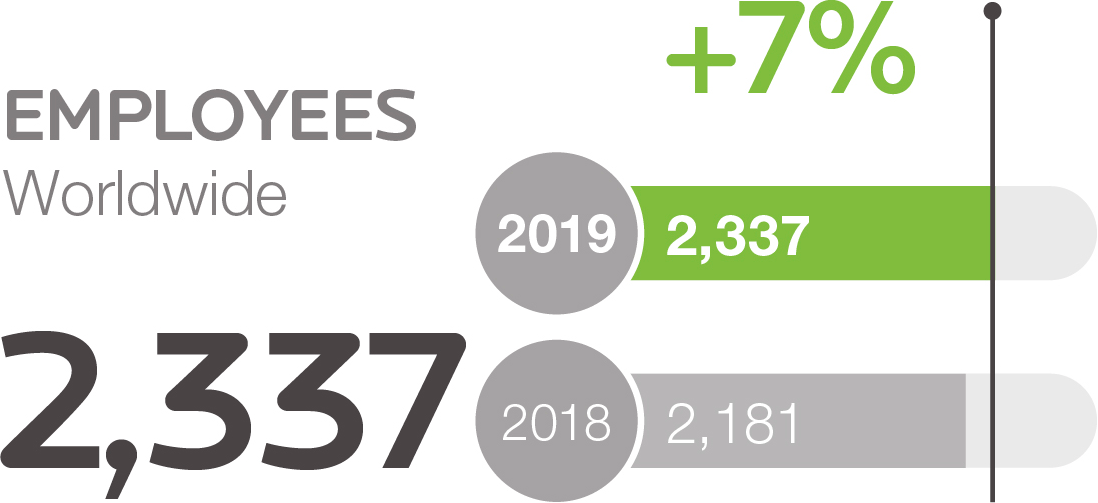

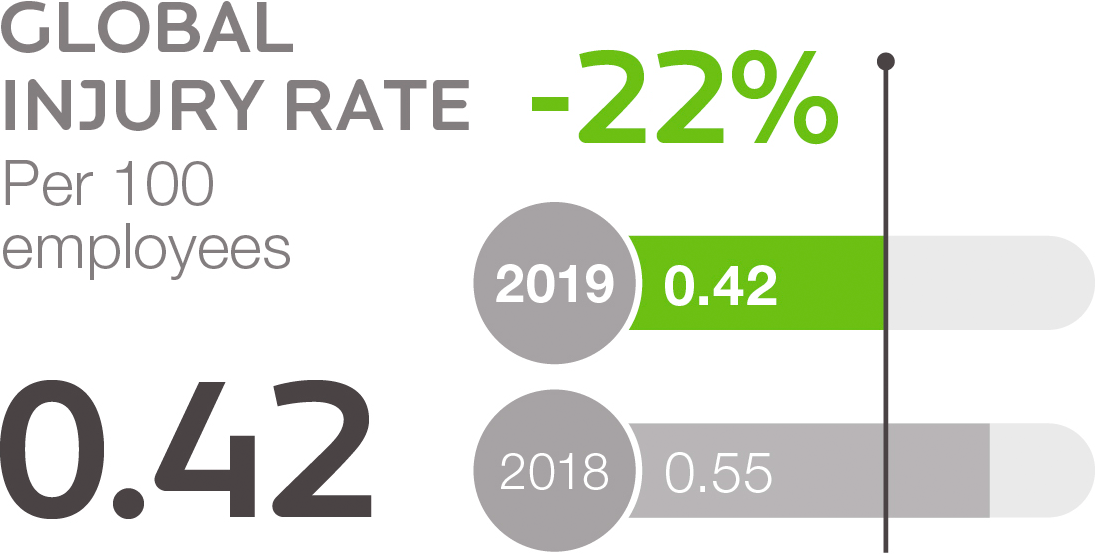

CONTINUED GROWTH

In 2019 we were successful in recruiting 407 people we needed to support our company’s growth, ranging from technicians building our products, to service engineers delivering high-quality support to our clients and people in R&D driving our innovations. Our total workforce, including temporary external workers, grew from 2,327 persons to 2,444 persons which includes 2,337 employees, a total increase of 5%. The number of employees within R&D positions increased by 13% to 612, which reflects 26% of ASMI’s total employees.

HEALTH & SAFETY

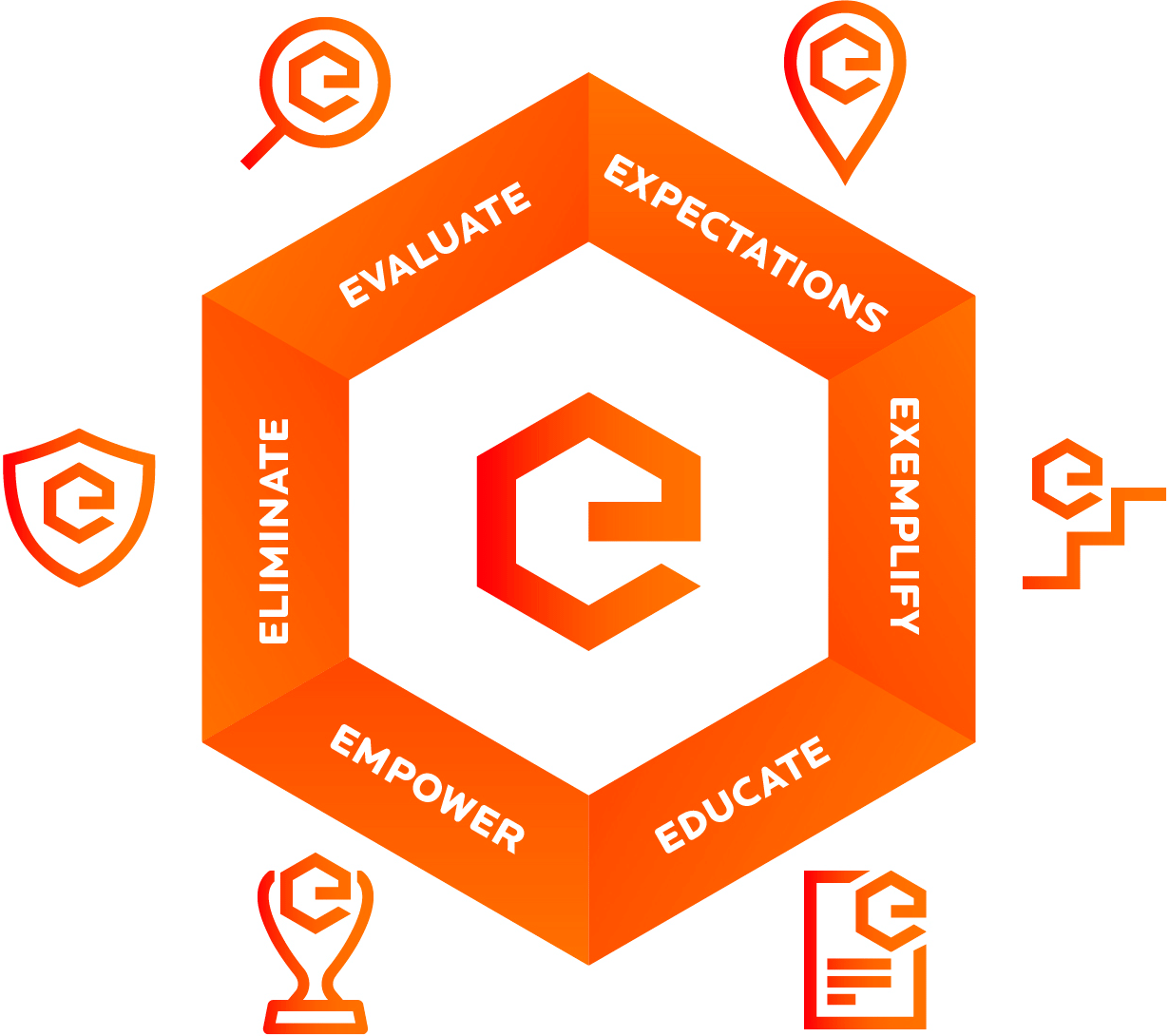

To ensure the safety of our people, and the people of our customers and suppliers, we always put safety first. Our philosophy is that any single injury is one too many. We remain diligent in pushing ourselves to improve in safety so that we can achieve ZERO HARM! To eliminate the risks and hazards that can lead to safety and health incidents, we are focusing on the key elements of safety leadership within the company. We believe that everyone should become a safety leader. We model this through our BeSafe – The 6Es of Safety Leadership framework, which empowers everyone to lead by example through taking action.

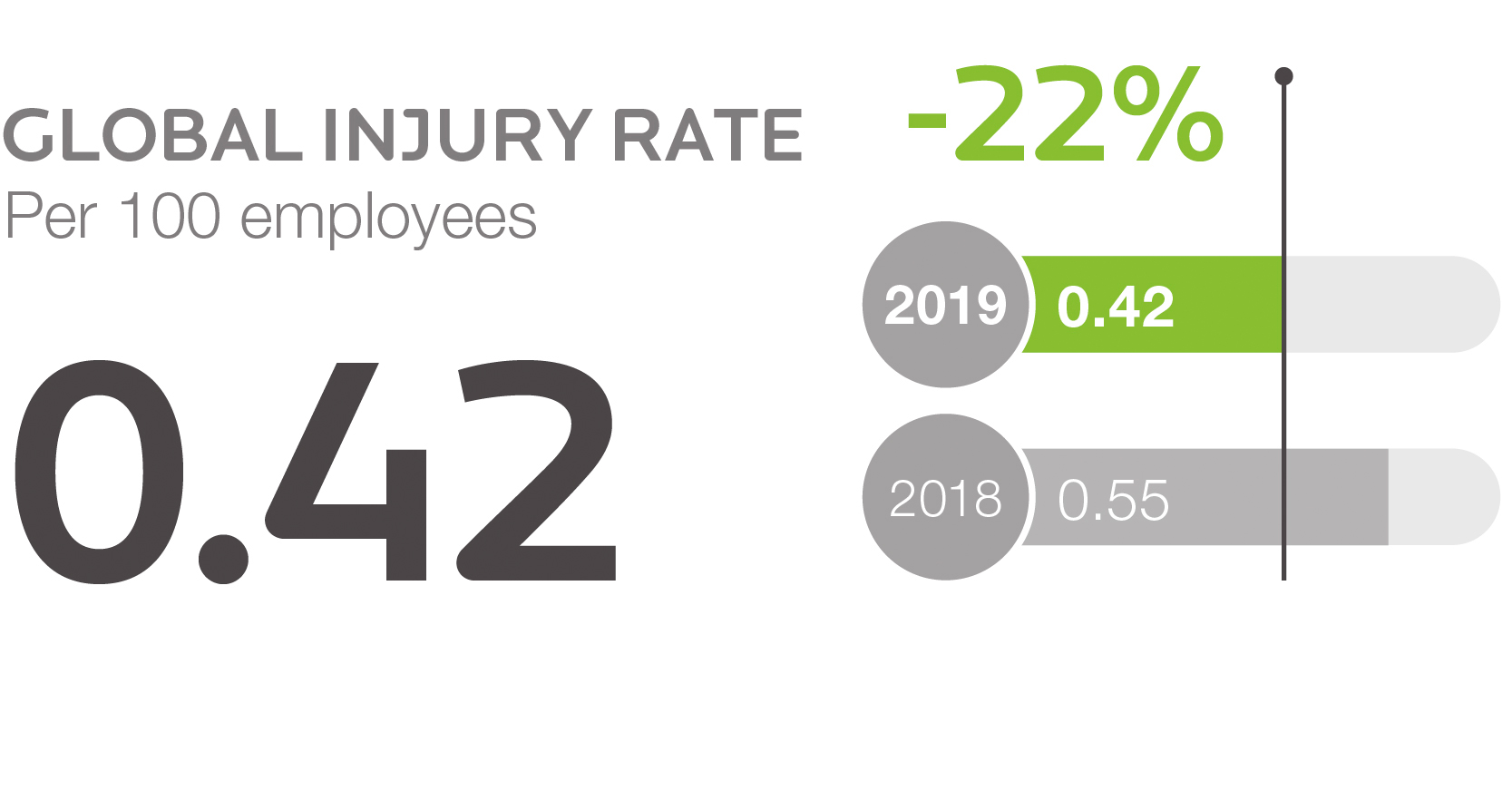

In 2019, our total injury rate showed a 22.3% improvement from 2018, while our recordable injury rate improved 6.7%.

BE SAFE SAFETY LEADERSHIP FRAMEWORK

CUSTOMERS

INVESTING LOCALLY,

COLLABORATING GLOBALLY

![]() We strengthen our global position by investing in our markets. From Asia to Europe to North America, we continue to invest locally while collaborating globally.

We strengthen our global position by investing in our markets. From Asia to Europe to North America, we continue to invest locally while collaborating globally.

BREAKTHROUGH TECHNOLOGIES

ASMI has a leading position in atomic layer deposition (ALD). ALD is our largest product line and continued to account for more than half of our equipment sales in 2019. ALD is the most advanced deposition method available in the market and makes it possible to create ultra-thin films of exceptional material quality, uniformity and conformality.

ALD is expected to be the fastest growing deposition market segment for the coming 3-5 years. As the industry moves to smaller geometries, more complex device structures, new materials and the need for more precise and conformal film deposition will further increase, which is expected to drive the growth of the ALD market.

We have a growing position in the market for epitaxy or Epi. Epitaxy is a process for depositing highly controlled silicon-based crystalline films. Epi is one of the fastest growing parts of the deposition market, with the number of Epi steps increasing as logic/foundry customers move to smaller nodes.

Our inroads in the market for advanced-node applications combined with a healthy development in the analog & power segment, drove substantial double digit growth in our Epi sales, which in 2019 has become our second largest product line, and another important growth engine in our portfolio next to ALD.

NEW PRODUCT INTRODUCTIONS

During 2019 we launched three new products. At the Semicon Korea trade show, we introduced the XP8 QCM tool for high-productivity plasma enhanced atomic layer deposition applications. This newest addition to our portfolio of leading ALD platforms allows for the integration of up to four quad chamber modules (QCM), each containing four process reactors, on a single XP8 platform. Thus an XP8 QCM tool supports up to 16 reactors, enabling high productivity.

In July at the Semicon West show, ASMI introduced the Previum process module for integrated pre-deposition surface cleaning. Integrated into the Intrepid ES epitaxy platform, Previum surface cleaning enables optimal quality epitaxial depositions for advanced node channel and source/drain engineering applications.

At the Semicon Europa show we launched the A400 DUO vertical furnace system with dual reactor chambers for wafer sizes of 200mm and smaller, targeting power, analog, RF, and MEMS applications.

SOCIETY

UNDERSTANDING OUR IMPACT,

INCREASING OUR VALUE

![]() We are increasingly aware of the impact we have as a company,

We are increasingly aware of the impact we have as a company,

and how this effects our value and society.

ENVIRONMENT

2019 is year four in our five-year environmental performance improvement cycle (from 2016-2020). We have sustained and continue to improve on the progress from 2017, exceeding the five-year objectives in both normalized greenhouse gas (GHG) emissions and water consumption. We strive to sustain the progress through 2020 with our new, larger facilities in South Korea (opened 2019, for R&D and Manufacturing) and Singapore (opening 2020, for Manufacturing) coming on-line.

In 2020, we will open a new facility in Singapore meeting the BCA Gold Plus Standard. This is a building energy and environmental design standard, and is above the basic requirements of design currently required in Singapore.

CIRCULAR ECONOMY

ASMI focused packaging reuse efforts on new product development and identified reuse opportunities with contract manufacturers in-region to practically evaluate the feasibility. We piloted the process in 2018 and then grew the program to include 5 product platforms in 2019 including example new product packaging displayed below. Through reuse of shipping packaging we were able to successfully avoid more than 25 tons of packaging waste this year.

MESSAGE FROM

THE CEO

Charles D. (Chuck) del Prado

Chairman of the Management Board,

President and Chief Executive Officer

KEY PERFORMANCE

FINANCIAL

NON-FINANCIAL

EMPLOYEES

GROWING PEOPLE,

GROWING BUSINESS

CONTINUED GROWTH

BE SAFE SAFETY LEADERSHIP FRAMEWORK

HEALTH & SAFETY

To ensure the safety of our people, and the people of our customers and suppliers, we always put safety first. Our philosophy is that any single injury is one too many. We remain diligent in pushing ourselves to improve in safety so that we can achieve ZERO HARM! To eliminate the risks and hazards that can lead to safety and health incidents, we are focusing on the key elements of safety leadership within the company. We believe that everyone should become a safety leader. We model this through our BeSafe – The 6Es of Safety Leadership framework, which empowers everyone to lead by example through taking action.

In 2019, our total injury rate showed a 22.3% improvement from 2018, while our recordable injury rate improved 6.7%.

CUSTOMERS

INVESTING LOCALLY

COLLABORATING

GLOBALLY

BREAKTHROUGH TECHNOLOGIES

ASMI has a leading position in atomic layer deposition (ALD). ALD is our largest product line and continued to account for more than half of our equipment sales in 2019. ALD is the most advanced deposition method available in the market and makes it possible to create ultra-thin films of exceptional material quality, uniformity and conformality.

ALD is expected to be the fastest growing deposition market segment for the coming 3-5 years. As the industry moves to smaller geometries, more complex device structures, new materials and the need for more precise and conformal film deposition will further increase, which is expected to drive the growth of the ALD market.

We have a growing position in the market for epitaxy or Epi. Epitaxy is a process for depositing highly controlled silicon-based crystalline films. Epi is one of the fastest growing parts of the deposition market, with the number of Epi steps increasing as logic/foundry customers move to smaller nodes.

Our inroads in the market for advanced-node applications combined with a healthy development in the analog & power segment, drove substantial double digit growth in our Epi sales, which in 2019 has become our second largest product line, and another important growth engine in our portfolio next to ALD.

NEW PRODUCT INTRODUCTIONS

During 2019 we launched three new products. At the Semicon Korea trade show, we introduced the XP8 QCM tool for high-productivity plasma enhanced atomic layer deposition applications. This newest addition to our portfolio of leading ALD platforms allows for the integration of up to four quad chamber modules (QCM), each containing four process reactors, on a single XP8 platform. Thus an XP8 QCM tool supports up to 16 reactors, enabling high productivity.

In July at the Semicon West show, ASMI introduced the Previum process module for integrated pre-deposition surface cleaning. Integrated into the Intrepid ES epitaxy platform, Previum surface cleaning enables optimal quality epitaxial depositions for advanced node channel and source/drain engineering applications.

At the Semicon Europa show we launched the A400 DUO vertical furnace system with dual reactor chambers for wafer sizes of 200mm and smaller, targeting power, analog, RF, and MEMS applications.

SOCIETY

UNDERSTANDING OUR

IMPACT INCREASING

OUR VALUE

ENVIRONMENT

2019 is year four in our five-year environmental performance improvement cycle (from 2016-2020). We have sustained and continue to improve on the progress from 2017, exceeding the five-year objectives in both normalized greenhouse gas (GHG) emissions and water consumption. We strive to sustain the progress through 2020 with our new, larger facilities in South Korea (opened 2019, for R&D and Manufacturing) and Singapore (opening 2020, for Manufacturing) coming on-line.

In 2020, we will open a new facility in Singapore meeting the BCA Gold Plus Standard. This is a building energy and environmental design standard, and is above the basic requirements of design currently required in Singapore.